Tri-ply stainless steel discs have turned into the key material of cooking utensils like woks, frying pans, milk pans and pressure cookers with high quality, directly influencing the products’ thermal conductivity and service life. As a professional tri-ply stainless steel disc manufacturer, we will systematically introduce how to evaluate the tri-ply stainless steel discs quality for kitchenware manufacturers and professional users to refer to.

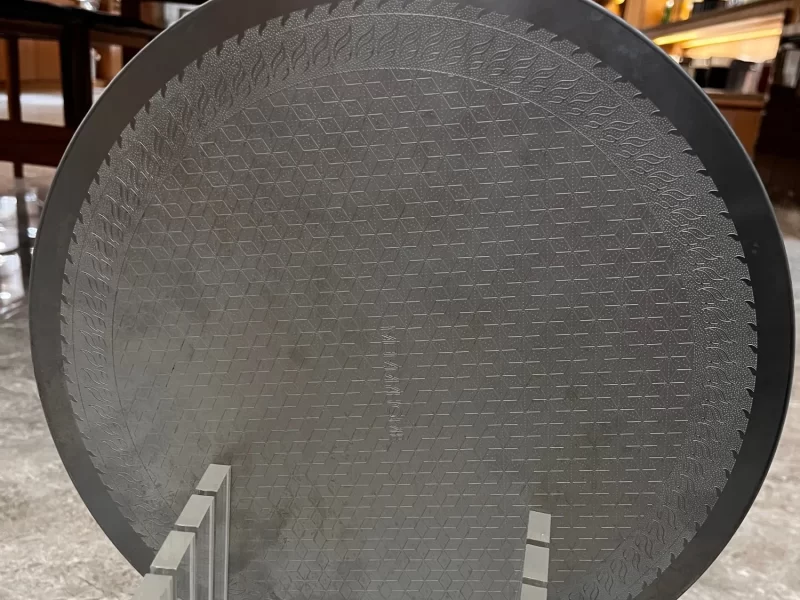

What is Tri-Ply Stainless Steel Disc?

Tri-ply is a structure that combines three metal materials through high-temperature and high pressure processes. The most common ones are 304 stainless steel in the inner layer, aluminum in the middle layer, and 430 stainless steel in the outer layer. This structure combines the advantages of multiple metals, making the cookware perform well in thermal conductivity, durability and adaptability.

How to evaluate the tri-ply stainless steel discs quality?

Material composition testing

The three-layer metal material of a high-quality Tri-Ply Disc must meet the following standards:

- Inner layer: Using 304/316 stainless steel to ensure food contact safety.

- Middle layer: It must be high-purity aluminum or copper to ensure fast and uniform heat conduction.

- Outer layer: 430 stainless steel must be magnetic and suitable for induction cookers.

Testing suggestions: Use a spectrometer to test the composition, focusing on checking the purity of the aluminum layer (impurities ≤ 0.5%) and the stainless steel grade certification. Or check the third-party test report provided by the supplier (such as SGS).

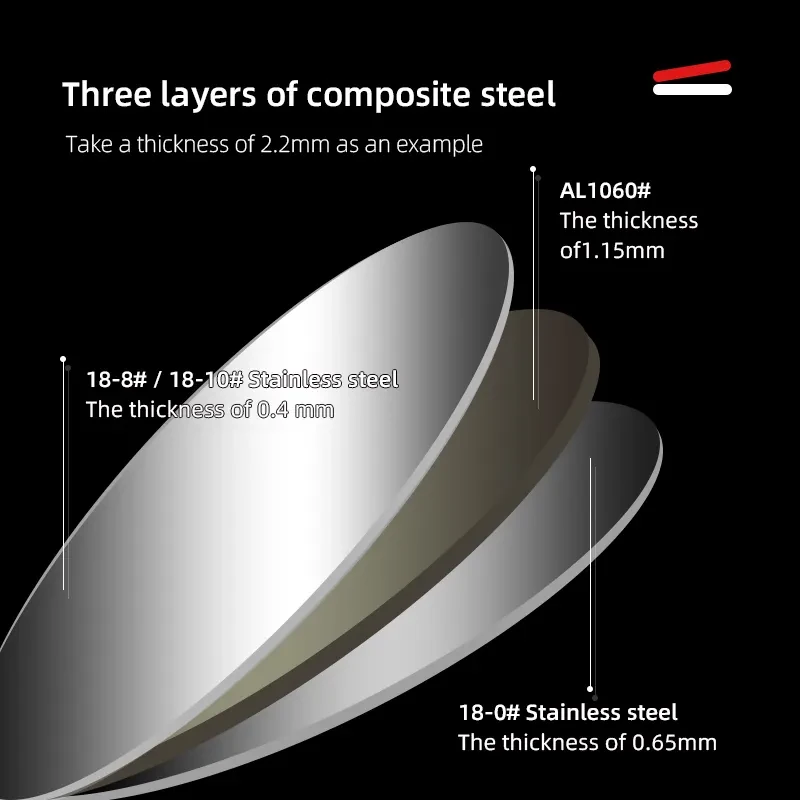

Thickness and uniformity

The total thickness and three-layer distribution of a high-quality Tri-Ply Disc must be uniform, with a common thickness:

- Total thickness: 2.5 mm- 5 mm

- Inner layer 304: 0.5 mm- 0.8 mm

- Middle layer aluminum: 1.5 mm- 3 mm

- Outer layer 430: 0.5 mm- 0.8 mm

Testing method: Use an ultrasonic thickness gauge to test the thickness at different points to ensure that there is no deviation between layers to avoid uneven heat conduction or bulging at the bottom of the pot.

Adhesion of composite layers

The three layers of metal must be completely bonded, without bubbles, delamination, or cold solder joints, otherwise, it will affect thermal conductivity and service life. The following tests can be used to ensure that the composite is tight:

- Ultrasonic flaw detection

- Mechanical shear test

- Cross-section cutting observation

Poor bonding will affect thermal efficiency and product service life.

Surface technology and corrosion resistance

The surface of a high-quality tro-ply disc should be:

- Smooth without scratches, pits or burrs.

- The food contact surface is mirror-polished or brushed.

- It has strong corrosion resistance. It is recommended to do a salt spray test (24-48 hours) to evaluate corrosion resistance.

Thermal conductivity test

The excellent tri-ply discs conduct heat quickly and evenly, avoiding the problem of “hot spots” on the bottom of the pot. Evaluation methods include:

- Heating uniformity test.

- Thermal imaging to detect heat distribution.

- Dry burning test to evaluate heat resistance.

Testing tools: infrared thermal imager and isotherm analysis software.

Magnetic permeability test

The outer layer of 430 stainless steel needs to have good magnetic permeability to be efficiently adapted to the induction cooker. It can be judged by a magnetic detector or a simple magnet test.

Conclusion

How to evaluate the tri-ply stainless steel discs quality? The following dimensions should be comprehensively examined:

- Whether the material composition meets the standard.

- Whether the thickness of each layer is uniform.

- Whether the three layers are firmly bonded.

- Is the surface smooth and corrosion-resistant?

- Is the heat conduction fast and uniform?

- Is the outer layer magnetic permeability qualified?

For professional cookware manufacturers, it is recommended to choose suppliers with ISO, SGS, RoHS, LFGB and other certifications, and require test reports and sample test data to ensure stable and reliable product quality.

As a leading stainless steel cookware supplier with more than 30 years of experience, Hengguang is committed to creating high-quality, durable, and excellent cooking results in tri-ply stainless steel cookware. To learn more about the tri-ply stainless steel discs manufacturing process and customization services, please contact us for samples and technical support.