Many cookware manufacturers and brands still struggle with recurring product issues that drive returns, complaints, and weak margins: uneven heating and hotspots, warping after repeated heating cycles, poor induction compatibility, inconsistent finish quality, and the cost of fully clad constructions. These issues translate into longer cook times, customer dissatisfaction, and higher warranty costs.

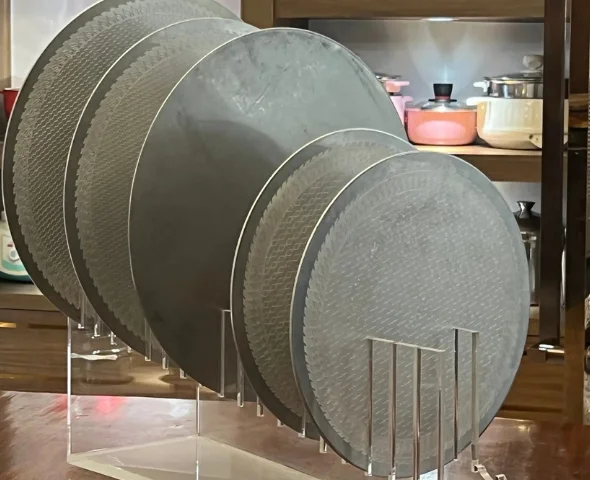

Hengguang, a supplier of tri-ply stainless steel discs, is bringing our products to address problems with your cookware. In cookware applications—frying pans, saucepans, pressure-cooker bases, and small kettles—tri-ply discs deliver faster, more even heating, improved flatness retention, and easier manufacturing at scale.

Why Tri-ply Works for Cookware

A tri-ply assembly (stainless steel / high-conductivity core / stainless steel) combines the surface properties and food safety of stainless steel with the thermal performance of an aluminum core. The result for cookware is measurable: faster heat spread, reduced energy waste, fewer hot spots (better cooking results), and greater structural stiffness—especially important for bases and pressure-service cookware.

Key commercial benefits for brands and OEMs:

- better cooking performance ⇒ improved consumer reviews

- lower return rates from deformation and delamination

- lower processing cost vs. fully clad bodies (disc bonding + attachment is simpler)

- straightforward induction compatibility when the outer layer is magnetic

Factory Wholesale Tri-ply Stainless Steel Disc Supply

Our factory manufactures and wholesales tri-ply stainless steel discs and pre-formed bases for cookware OEMs, contract manufacturers, and appliance brands. We support small trial runs and high-volume production, and we provide technical support for integration into your assembly line (welding, clinching, laser trimming, and edge sealing).

Why procurement teams work with us:

- Factory direct pricing

- Precise dimensional and quality control

- Reliable and stable supply

- Flexible MOQs suitable for sampling and scaling to mass production

- Dedicated QC and third-party testing on request

- OEM/ODM support: custom diameters, thicknesses, markings, surface finishes, and packaging

Advantages of the tri-ply stainless steel disc

- Excellent thermal conductivity: The middle layer of triply stainless steel discs is made of aluminum with high thermal conductivity, which effectively improves the overall thermal conductivity. In the field of stainless steel cookware, using thinner discs will heat the cookware faster, which is generally used in the manufacture of pans and milk pans. Using thicker discs will make the overall thermal conductivity of the cookware uniform, which is generally used in the manufacture of large cookware such as woks.

- Excellent durability: The outer and inner layers are made of high-quality stainless steel, which has extremely high durability. In the field of manufacturing stainless steel cookware, it can significantly improve the service life and performance of the product and meet the needs of high-frequency use and harsh environments.

- Wide range of applications: triply stainless steel raw materials are widely used in cookware manufacturing, industrial manufacturing, and medical device manufacturing. It is an excellent material.

- Accurate size: Our manufacturing process can accurately control the size and thickness of the disc, ensuring that each product meets the standards in terms of weight, thickness, and flatness.

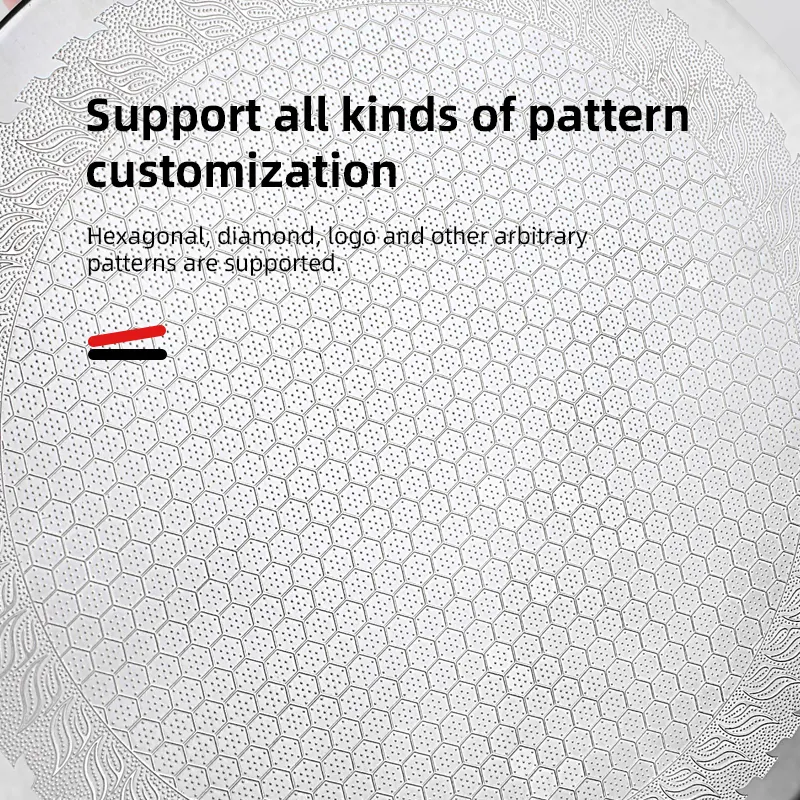

Customization Tri-Ply Stainless Steel Disc Options

Customizable Thickness Options: Available in 1.8mm, 2.0mm, 2.2mm, 2.5mm, and 3.0mm thicknesses, with full support for custom thicknesses.

Pattern Customization: Supports a variety of patterns, including hexagonal, diamond, logos, and other bespoke designs, offering full creative flexibility.

Material: 304/316 Stainless Steel + Aluminum + 430 Stainless Steel

Size: Customize different sizes of the tri-ply stainless steel disc.

Shapes: Round Plates / Any special shape. The circular size can be 250mm-500mm. Special-shaped size can be 900mm.

MOQ and Lead Time

Standard terms we offer (or negotiable by project):

- MOQ: samples from 100 pcs; production orders from 1,000 pcs (lower MOQ negotiable for development).

- Lead time: 2–6 weeks after sample approval, depending on quantity and customization.

- Pricing: depends on material mix, total thickness, diameter, and finishing—volume discounts apply.

Conclusion

If you are evaluating base solutions for new SKUs or replacing single-layer bases with a performance upgrade, request our technical sample pack. We will supply a tailored RFQ template and collaborate on tolerance, finish, and attachment design to fit your production line.

Contact our B2B sales engineer to request samples, technical drawings, or a factory audit schedule. Provide your preferred diameter, total thickness, and intended cooktop types (gas/induction) to receive an initial quotation and lead-time estimate.

Cookware Made of Tri-Ply Stainless Steel Disc From Hengguang

About Hengguang

As one of the top stainless steel kitchenware manufacturers, not only are we supplying tri-ply stainless steel discs for B2B clients, but we also support wholesale stainless steel cookware and custom stainless steel kitchenware solutions.

Dated back three decades, we were just a start-up. Now, Hengguang has grown into a comprehensive enterprise with 3 factories and more than 300 employees. We always adhere to the principles of quality first, technological innovation, and customer satisfaction, and constantly expand and improve our production capabilities.

Working with Hengguang, you will gain:

✅Large production scale

✅Global logistics network

✅Raw material factory

✅Quality service