In the selection of kitchen equipment and kitchenware, the choice of stainless steel grade directly affects equipment lifespan, maintenance costs, and food safety. The two most common types of stainless steel used in food contact are 304 and 316. On the surface, it may seem like a difference of only a few digits, but under actual working conditions, such as salt, cleaning intensity, temperature, and contact time, there will be significant differences in their performance

In this blog, Hengguang, as a leading stainless steel kitchenware manufacturer, will assist procurement personnel in determining: under which kitchen environments is 304 sufficient? When should 316 be prioritized? And provide clear Selection suggestions of 304 vs 316 procurement and operational recommendations.

Chemical Essential Differences Between SS304 and SS316

Simply put, both 304 and 316 belong to austenitic stainless steel(stainless steel that is added nickel and chromium, not easy to rust, not afraid of acid and alkali, and not magnetic to the touch), but 316 contains a certain proportion of molybdenum (Mo), which makes its resistance to pitting and crevice corrosion significantly better than 304 in the presence of chloride ions (Cl ⁻).

- 304 (common ingredients): about 18% chromium (Cr), 8-10% nickel (Ni); Good corrosion resistance, suitable for most food contact scenarios.

- 316 (Common Ingredients): Contains molybdenum (about 2-3% Mo), with components of about 16-18% Cr, 10-14% Ni, and 2-3% Mo; It performs more robustly in environments containing salt and chlorine.

The presence of molybdenum is not a “universal cure”, but in situations where chloride ions are locally concentrated due to sea salt, pickling, or high chlorine cleaning agents, the advantages of 316 will significantly increase over time: welds, bolt holes, and gaps are less prone to pitting corrosion, thereby reducing the risk of leakage and failure.

Common Forms and Causes of Corrosion in Kitchens

In the kitchen environment, there are several common types of corrosion phenomena, each of which has specific causes behind it:

Pitting corrosion

Mechanism: Chloride ions damage the passivation film on the surface of stainless steel, causing local corrosion and forming small pores at small defects.

Causes: salt spray, seafood/saltwater residue, chlorine-containing cleaning agents; Often occurs in areas with scratches or poor polishing.

Crevice Corrosion

Mechanism: Fluid trapped in small gaps such as seams, gaskets, and handle roots of appliances causes differences between the microenvironment of these areas and the external environment. Over time, the acidic substances and chloride ions in the retained liquid continue to concentrate, forming a highly corrosive “microenvironment” in these localized areas, thereby accelerating the corrosion of the stainless steel surface.

Attention: Welding joints, rivets, and handle interfaces are the most prone to occur.

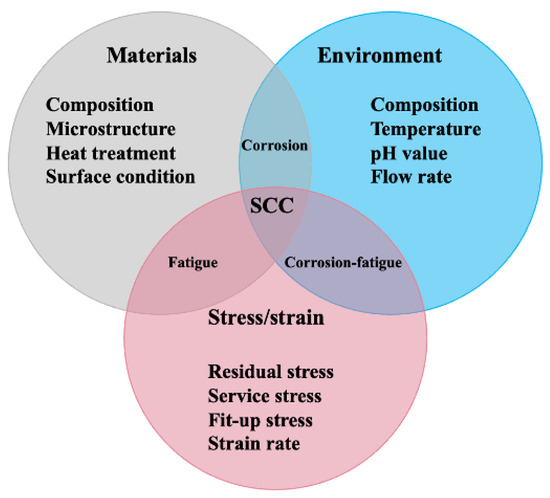

Stress Corrosion Cracking (SCC)

Mechanism: Cracks are generated under the combined action of tensile stress (structural stress) and corrosive environments (such as high chlorine and high temperature).

Attention: It often occurs near the stressed area or weld seam.

Chemical/mechanical factors

Common factors in the kitchen: Strong alkalis/oxidants (such as high-concentration chlorine bleach), high-temperature dishwasher cycles, long-term humidity, and salt crystallization can accelerate the corrosion process.

Detection signal: The appearance of black spots, small pits, discoloration at the weld seam, or local leakage on the surface is all early warnings and should be promptly addressed or evaluated for replacement needs.

Performance of Materials in Different Kitchen Environments

Below are the actual performance, common problems, and suggestions of 304 and 316 in different kitchen environments:

Home Kitchen (Ordinary Urban Household)

- Conclusion: 304 is usually sufficient.

Performance of 304:

Home kitchens are usually not exposed to high chlorine or high salt conditions for a long time. The concentration of cleaning agents is mild, and the ventilation and drying conditions are good. Therefore, 304 has a high cost-effectiveness in terms of cost and performance. Common kitchen utensils, sinks, tableware, etc., using 304 can meet the needs of many years of use.

316 Performance:

Although it has better performance, its premium is difficult to recoup in a short time in most household scenarios.

- Suggestions: If the kitchen occasionally handles seafood, pickled foods, or is located by the sea, it is recommended to prioritize using 316 for critical contact areas such as sinks, fasteners, and handles. Overall, 304 is still the main material, with emphasis on polishing and passivation treatment to reduce the risk of starting point corrosion.

Seaside/Seafood Restaurant/Fishing Port Kitchen (High Salt Environment)

- Conclusion: 316 is highly recommended.

Problem with 304:

Salt spray and humid environments can cause pitting and crevice corrosion in 304 over several months to years, especially at joints and welds; High maintenance costs and replacement frequency.

Advantages of 316:

The presence of molybdenum greatly enhances the tolerance to chloride ions, significantly improves equipment lifespan and reliability, and reduces downtime and replacement costs.

- Suggestion: The main equipment (washing tank, processing table, containers in direct contact with seawater) should use 316; All fasteners, rivets, and handles should also use 316; Require post-weld polishing and passivation treatment, while establishing regular salt/scale removal maintenance (daily flushing, regular freshwater wiping and drying).

Chain Restaurant/High Turnover Commercial Kitchen (With Dishwashers and Strong Cleaning Agents)

- Conclusion: Depending on the cleaning process and disinfectant, there is a preference for 316 or 304 with surface strengthening treatment.

Problem point:

The use of high-temperature dishwashers, chlorine-containing disinfectants, or improper bleaching agents can cause cumulative damage to the passivation film of 304, especially in the gaps and welds where localized corrosion may occur.

316 performance:

More durable in strong cleaning and chemical exposure environments, can reduce long-term maintenance frequency.

- Suggestion: If your cleaning system includes high-concentration chlorine disinfection or high-temperature cycling, it is recommended to use 316 for key parts of the equipment, or require 304 products to undergo higher levels of polishing and chemical passivation before leaving the factory; Simultaneously, optimize the cleaning agent formula (reduce chlorine concentration, choose stainless steel-friendly disinfection alternatives) to extend its lifespan.

Outdoor/Temporary Kitchen/Camping (Climate Change Scene)

- Conclusion: Short-term/occasional use of 304 is feasible; Choose 316 for long-term or outdoor activities by the sea.

Key points:

The outdoor environment fluctuates greatly (humidity, salt air, temperature difference), and the cleaning conditions are limited. Short-term use of 304 is cost-effective, but if used by the seaside for a long time, 316 can significantly reduce the risk of oxidation and pitting.

- Operation suggestion: Regardless of the material, outdoor equipment storage and drying management are crucial: thoroughly clean fresh water and air dry after use to avoid salt crystallization residue.

Food Processing Plant/Sauce Factory (Long-term Acidic/Salt Treatment)

- Conclusion: Prioritize 316 or higher grade alloys.

Why strict: Long-term exposure to acid, salt, hot steam, and process chemicals can accelerate pitting and crevice corrosion of 304, affecting product safety and equipment integrity.

The importance of 316: In continuous production lines and equipment with many gaps (pumps, valves, mixing containers), 316 significantly reduces failure rates and downtime risks.

- Procurement suggestion: Mandatory use of 316; Require material certification, welding, and passivation certificates, and conduct working condition simulation during acceptance (such as salt/acid wet heat cycle testing); Try to minimize gaps during design and use matching 316 fasteners.

Conclusion

Ordinary households and most indoor restaurants: Priority should be given to 304 (high cost-effectiveness), and 316 can be used locally in key areas or high-exposure points (such as sinks and fasteners).

Seaside, seafood restaurants, and fishing port processing: It is strongly recommended to use 316 (including fasteners and handles) as a whole, and require polishing and passivation after welding.

High-turnover commercial kitchens and food processing: If high-intensity cleaning/chemical disinfection is used, it is recommended to perform stricter surface treatment and maintenance on 316 or 304, and if necessary, request salt spray/pitting test reports in the RFQ.

Outdoor/Temporary Application: Short-term 304 available, long-term or seaside scenes prefer 316; Anyway, emphasize cleanliness and dryness management.

About Us

Hengguang, a leading stainless steel kitchenware manufacturer, has been specializing in stainless steel kitchenware in the industry for decades. We are confident in pronouncing our product quality and expertise. Our stainless steel kitchenware is built to deliver exceptional performance while ensuring long-lasting quality and safety for every meal.

We provide custom stainless steel kitchenware solutions, offering OEM and ODM services that allow your business to create unique, market-driven products. From innovative designs to advanced manufacturing techniques, Hengguang delivers stainless steel kitchenware that meets the highest international standards.