When you see “food-grade stainless steel cookware” as part of a product specification, what does it mean? In short, it means that its composition, manufacture, and testing meet standards for safe contact with food; low metal leaching, good corrosion resistance, and hygienic surfaces.

This article explains the grades, the relevant manufacturing steps, what tests and certifications to ask for, and a practical checklist for those who might use this as a homeowner, retailer, or sourcing professional. And Hengguang, a professional stainless steel manufacturer, is offering wholesale food-grade stainless steel cookware supply.

What “food-grade” Really Means

“Food-grade” is not a single designation. It is a combination of material chemistry, surface treatment, and compliance testing. On the material side, food-grade stainless steels have resistance to corrosion and minimize the migration of ions into food. On the process side, appropriate cleaning, passivation, and welding practices limit opportunities for contamination. On the compliance side, laboratory testing and certificates of compliance (FDA, LFGB, EU Reg 1935/2004, China GB standards) confirm that the product is safe for normal use.

Common Stainless Steel Grades Used in Cookware

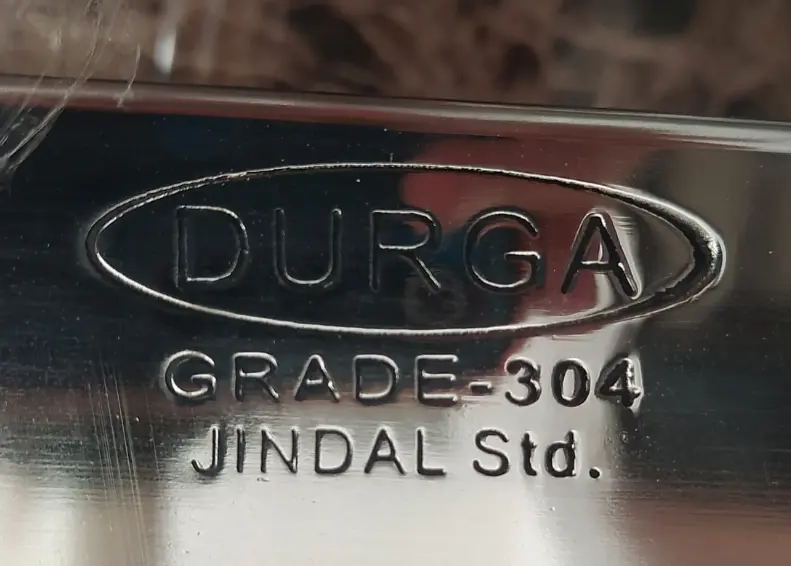

- 304 (18/8 or 18/10) — the most common food-grade alloy. Balanced corrosion resistance, shine, and formability. Widely used for general-purpose food-grade stainless steel cookware.

- 316 / 316L — contains molybdenum for improved resistance to chlorides and salt; recommended for coastal or industrial kitchens.

- 430 (18/0) — ferritic, magnetic, and lower cost; sometimes used as an induction-friendly base but less corrosion-resistant on food-contact surfaces.

- 201 / 202 — economical alternatives with reduced nickel; not ideal for long-term food exposure in corrosive conditions.

Knowing the grade on a spec sheet helps match cookware to environment: 304 suits most homes; 316 is worth the premium for seaside restaurants or harsh cleaning conditions.

Manufacturing Steps that Affect Safety

Material grade alone isn’t enough. These process controls determine whether that grade behaves like true food-grade stainless steel cookware in the field:

- Passivation: chemical treatment removes free iron and restores the chromium oxide passive layer. Proper passivation dramatically improves corrosion resistance.

- Surface finish: smoother surfaces (electropolish or fine polish) reduce crevices that can trap food or bacteria and are easier to clean.

- Welding quality (TIG/laser): clean, properly shielded welds prevent contamination and maintain corrosion resistance at joints.

- Coatings & linings: if a nonstick or decorative coating is used, it must be food-safe (PFOA-free, tested for migration) and properly bonded to the substrate.

- (PFOA-free, tested for migration) and properly bonded to the substrate.

Tests & Certifications to Ask For

For B2B buyers and cautious consumers, request documentation for the food-grade stainless steel cookware — not just a label. Important items include:

- MTR (Mill Test Report): verifies the chemical composition of the plate/coil used.

- Migration / heavy-metal tests: show levels of Ni, Cr, Pb, Cd — ensure they are below regulatory limits.

- Salt spray/pitting tests: simulate corrosion resistance in aggressive environments.

- Regulatory certificates: LFGB (Germany), FDA (US), EU Reg 1935/2004, China GB standards — relevant depending on target market.

- Functional testing: dishwasher cycles, thermal cycling, warp tests, and abrasion/scratch tests.

For large buys, require batch traceability and retention of test reports so you can audit later.

Practical Buying Checklist

When buying wholesale food-grade stainless steel cookware, these practical items should be checked:

- Material grade on label: 304/18-10 or 316 explicitly stated.

- Construction: tri-ply/fully-clad vs disc-clad; specify total clad thickness (mm).

- Finish & passivation: electropolish or passivation certificate required.

- MTR availability: ask for mill certificates per batch.

- Certs & lab reports: request LFGB/FDA/EU/GB test reports as applicable.

- Sample tests: request warp test, induction compatibility, and a searing/deglaze cooking sample.

- Warranty & after-sales: define defect policies, spare parts, and replacement thresholds.

Care & Use to Preserve Safety

Even certified cookware requires proper care: avoid prolonged contact with strong chlorides (bleach), rinse and dry promptly after washing, and replace gaskets or damaged parts. Minor surface discoloration or “rainbow” tints are cosmetic and removable by vinegar; rust spots are repairable if treated early. Good care maintains both safety and appearance.

Conclusion

When it comes to purchasing food-grade stainless steel cookware, it is important to pay attention to both the material and manufacturing process: knowing the alloy, the finish, passivation, and testing documentation. For retailers and purchasing departments, you need to receive the MTRs and laboratory reports. For home cooks, you want to trust the 304/18-10 tri-ply cookware with a decent finish and unequivocal care instructions.

About Hengguang – Your Reliable Stainless Steel Cookware Supplier

Hengguang is a manufacturer of stainless steel kitchenware specializing in stainless steel kitchenware production. Our tri-ply stainless steel construction gives you better heat distribution, strength, and cooking performance.

With standardized production processes and strict quality control, every kitchenware from your custom food-grade stainless steel cookware solution meets international standards. As a respected supplier of stainless steel kitchenware, we give you the benefits of large-scale manufacturing and the strength of wholesale purchase; this translates into reliable supply and quick delivery for our global partners.

FAQ — Quick Myths About Stainless Steel Cookware

Q1: Is all stainless steel the same?

A1: No — different grades (304, 316, 430, etc.) and manufacturing processes (polishing, passivation, weld quality) determine corrosion resistance and safety.

Q2: Does higher nickel content make stainless steel unsafe?

A2: No — in food-grade alloys, nickel stabilizes the structure; its levels are regulated and safe for cookware.

Q3: Is a product label that simply says “stainless” sufficient?

A3: No — ask for the alloy grade, MTR (mill test report), and relevant test reports to verify compliance.