In modern kitchens, three-layer stainless steel cookware is popular for its balanced performance and practicality. One of the core contributors to this is the scientific application of the material’s thermal conductivity, which acts like an invisible engineer, silently coordinating heat between the metal layers, bringing you an excellent cooking experience.

Thermal conductivity: the secret for heat transformation in a three-layer structure

Thermal conductivity (unit: W/m·K) measures the ability of a material to conduct heat. Briefly speaking, the higher the thermal conductivity, the faster the food heats up and the shorter the cooking time. In the sophisticated design of the three-layer cookware, the difference in thermal conductivity of the different metal layers is utilized properly.

Stainless steel outer layer (thermal conductivity ≈ 16 W/m·K): It provides structural strength and corrosion resistance, but has weak thermal conductivity

Aluminum/copper middle layer (aluminum ≈ 237 W/m·K, copper ≈ 401 W/m·K): As the core thermal conductive layer, it quickly absorbs the heat from the stove and diffuses it around

Stainless steel inner layer: Direct contact with food, meanwhile, this layer can ensure user safety and Product durability.

The “sandwich structure”, which is applied to three-layer cookware, is used to make up for the shortage of conductivity of stainless steel through high thermal conductivity materials to achieve performance complement.

How does thermal conductivity determine the key performance of three-layer cookware?

Heating uniformity: Say goodbye to partial burning

When the bottom of the pot contacts the heat source, the aluminum/copper layer quickly transfers the heat horizontally to the entire bottom of the pot with its high thermal conductivity. It can quickly and evenly distribute the heat to the entire pot surface, allowing the food to be heated more evenly, reducing the situation of burning the bottom or uneven heating. Experiments show that the heat distribution uniformity of the three-layer pot is more than 50% higher than that of the single-layer stainless steel pot. We can, therefore, infer that when frying steak, there will no longer be the embarrassing scene of the center being burnt and the edges being half-cooked, and the sauce will also have fewer lumps when boiling.

Energy efficiency: The secret to saving energy

High thermal conductivity directly shortens the preheating time. For example, a three-layer milk pot boils milk 30% faster than a single-layer pot because of the fabulous heat conductivity of the aluminum core. Under the same situation, gas or electricity consumption will be saved significantly over a long period of usage.

Temperature response: The key to precise temperature control

The high thermal conductivity of the copper/aluminum layer makes the pot more sensitive to heat adjustments. When the flame is turned down, the heat dissipates quickly to avoid boiling over; when the flame is turned up, the temperature rises quickly, which is suitable for dishes that require precise temperature control (such as melting chocolate, French sauces, etc).

Why are aluminum and copper the first choice for the thermal conductive layer of three-layer cookware?

Aluminum is a cost-effective choice: Although copper has a higher thermal conductivity than aluminum (401>237), aluminum has better attributes for heat transformation and lower cost, so it can meet most home cooking needs

Copper has professional-grade performance: High-end cookware tends to use copper because of its excellent thermal conductivity, which is suitable for precision operations such as molecular cooking, but it is expensive and requires maintenance

The art of balancing thickness in three-layer cookware: The thickness of the middle layer needs to be accurately calculated (usually 1.5~3mm). Too thin of it will result in insufficient thermal conductivity; on the contrary, it will increase weight and may reduce thermal response speed.

Beyond thermal conductivity: the synergistic advantage of the three-layer structure

Although thermal conductivity is the core, the three-layer design also solves other key issues:

Deformation resistance: The composite structure disperses thermal stress and reduces the risk of warping of single-layer stainless steel at high temperatures

Induction cooker compatibility: The outer layer of magnetic stainless steel ensures the normal use of the induction cooker, the inner layer ensures food safety, and the aluminum/copper layer focuses on thermal conductivity – each layer does its job well.

Hot and cold shock protection: The aluminum/copper layer buffers temperature changes and reduces the risk of cracking caused by sudden cold and hot

Use and maintenance: keep the thermal conductivity as good as new

To maintain the thermal conductivity of three-layer cookware, please note:

Avoid empty burning: the aluminum layer may melt and deform at high temperature, destroying the sandwich structure

Gentle cleaning: Scratching with steel wool will damage the surface and affect the heat reflection efficiency. It is recommended to use a soft cloth plus neutral detergent to clean it.

Moisture-proof storage: long-term water stains may corrode the joints between layers and shorten the service life

The invention of three-layer cookware is the precise response of material science to cooking needs. It uses the difference in thermal conductivity to weave an efficient thermal network, allowing heat to reach every corner precisely, and this is the temperature philosophy that technology has given to modern kitchens.

Next time you use a three-layer pot to cook a pot of dense cream mushroom soup, don’t forget to thank the invisible layer of aluminum or copper: it silently coordinates the energy of the flame, making cooking a controllable art.

How to choose and buy three-layer cookers

When choosing a three-layer cooker, you can decide based on the following points:

Stove type: Make sure the selected cooker is compatible with your stove type.

Capacity requirements: Choose a cooker with appropriate capacity based on the number of family members or commercial use.

Quality assurance: Choose a brand with quality assurance to ensure that the material and workmanship of the product meet the standards.

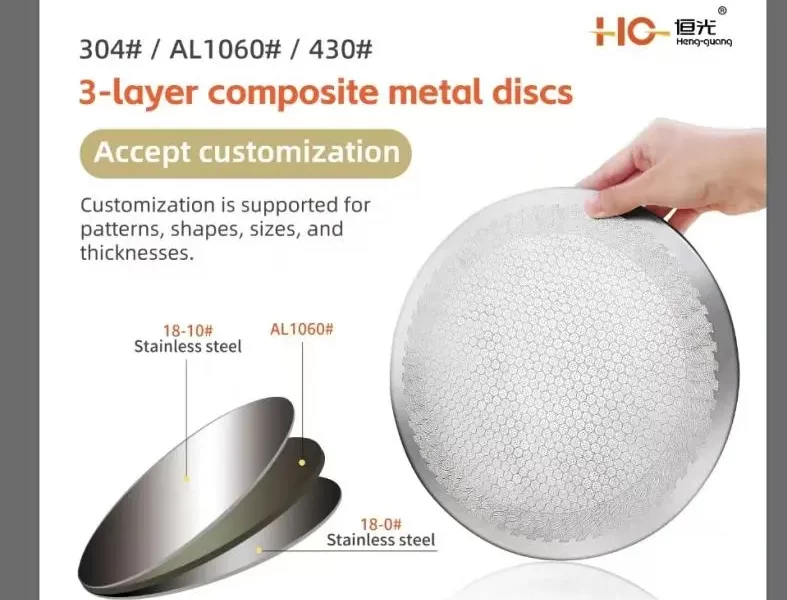

About Hengguang

Hengguang focuses on the field of stainless steel disc manufacturing and is committed to providing precision processing and customized solutions for global customers. We use advanced production technology and a strict quality inspection system. Our products cover a variety of specifications and are widely used in kitchen supplies and other fields. We support customization according to drawings, small batch trial production, to large-scale production, with fast response and flexible delivery as our core competitiveness.

We look forward to becoming your trusted partner with the ingenuity of metal precision manufacturing.