When sourcing or selling stainless steel cookware internationally, certification is not optional — it’s a commercial requirement. Two of the most requested references in procurement and retail are Germany’s LFGB testing and the U.S. FDA compliance framework. Together, they form the backbone of credible stainless steel cookware certification for buyers, importers, and brands.

As a top kitchenware manufacturer, Hengguang, in this article, explains what each regime checks, how they differ, why B2B buyers insist on them, and what practical steps you should require from suppliers before placing an order.

What the LFGB Certification Means for Stainless Steel Cookware

LFGB (Lebensmittel- und Futtermittelgesetzbuch) is the German food and feed code that functions as a de facto gold standard for material safety in the EU. For finished cookware, LFGB testing focuses on product safety in real-use conditions. Key points:

- Overall migration testing. LFGB tests whether substances migrate from metal into food simulants under defined temperature/time regimes. This reveals whether the cookware could contaminate food during boiling, simmering, or acidic cooking.

- Heavy metal release. Nickel, chromium, and other trace metals are measured against strict thresholds. Even in food-grade alloys, batch variability or poor surface treatment can increase release rates.

- Sensory testing. LFGB includes odor/taste assessments — cookware must not impart off-odors or flavors to water or food simulants. This is something many non-EU standards don’t test.

- Applicable use cases. LFGB reports commonly specify which uses were tested (e.g., boiling, acidic food contact, high-temperature). Buyers rely on those specifics when assigning SKUs to target markets.

For dealers and brands selling into the EU, an LFGB test report for the finished article is strong evidence of safety — and often a purchase gatekeeper for e-commerce platforms and retail chains.

What FDA Compliance Means for Stainless Steel Cookware

The U.S. Food and Drug Administration uses a different approach: it regulates food-contact materials through a framework of acceptable substances and recommended practices rather than a single named “certification.” For cookware buyers, the practical implications are:

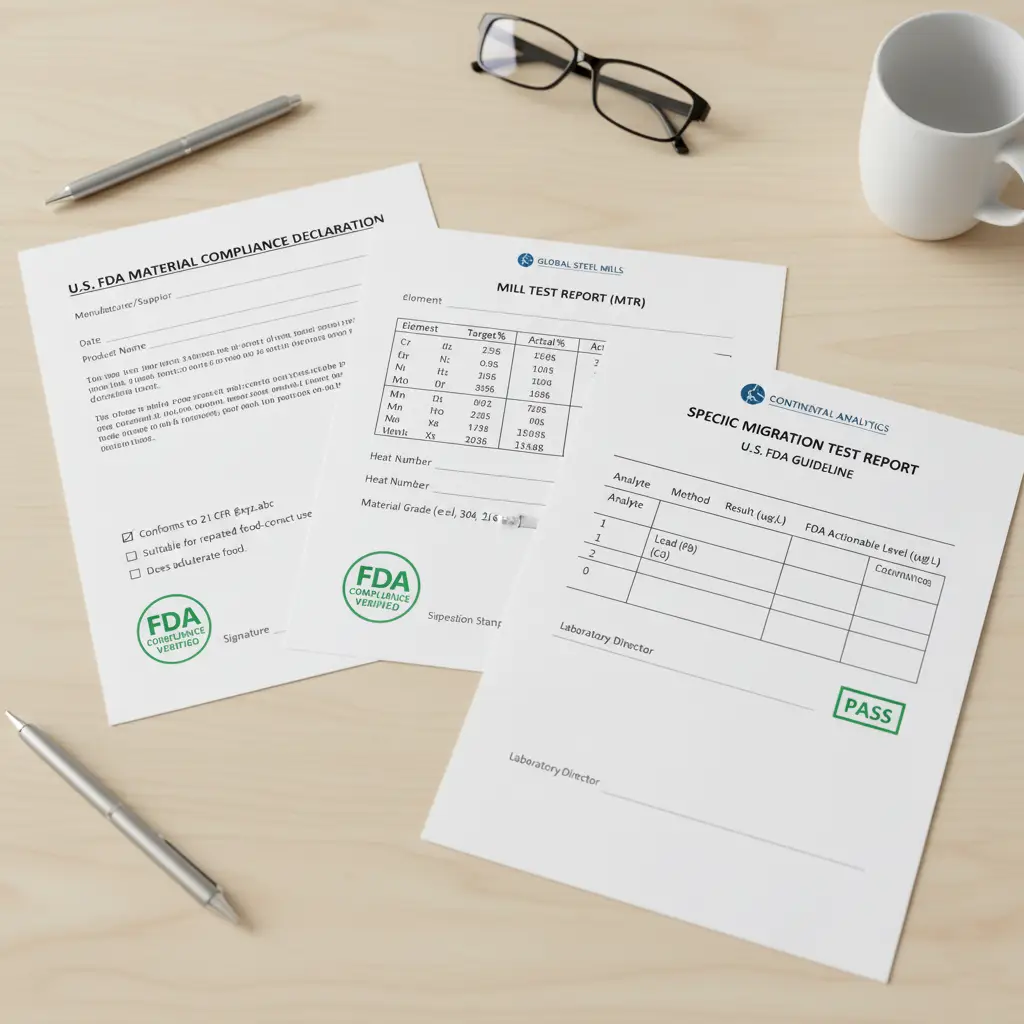

- Material compliance and declarations. Suppliers must demonstrate that the alloy and any coatings conform to FDA food-contact guidance and are suitable for intended use. For stainless steel, this often means providing composition documents and MTRs (Mill Test Reports).

- Migration and heavy-metal considerations. While the FDA has specific action levels for some contaminants, U.S. compliance is often shown via lab reports or by relying on recognized safe materials such as 304/316 stainless steels.

- Documentation over a single pass/fail stamp. U.S. importers typically require supplier declarations, batch MTRs, and, when necessary, third-party migration/heavy-metal tests.

In short, FDA compliance is essential for the North American market, but it is commonly interpreted through material traceability plus targeted lab tests rather than a single consumer-facing certificate.

LFGB vs FDA — Key Differences Buyers Must Know

| Topic | LFGB | FDA |

|---|---|---|

| Nature | Product-level tests (migration, sensory) | Material/composition guidance and targeted testing |

| Focus | Migration, odor/taste, finished article | Composition, allowed substances, declared compliance |

| Regional weight | Europe (especially Germany) | United States, North America |

| Buyer implication | Require finished-article LFGB report | Require material MTRs + relevant lab tests/supplier declarations |

Two practical takeaways: LFGB is typically more prescriptive and tests for sensory effects; FDA expects traceable material control and appropriate lab evidence. For cross-border sellers, complying with both regimes provides the widest market access and the fewest surprises.

How Stainless Steel Cookware Certification Drives Procurement Decisions

A cookware certification package reduces procurement risk in measurable ways:

- Faster market entry. Retailers and e-commerce platforms (notably Amazon EU) often ask for LFGB or equivalent test reports to clear listings. Having them up front shortens onboarding time.

- Lower technical risk. Certification reduces the chance of recalls, customer complaints, and shipment holds — all costly disruptions for distributors and brands.

- Premium positioning. High-end buyers want to see full test documentation; LFGB is often used as a marketing and trust signal for premium lines.

- B2B acceptance. Institutional buyers (hotels, hospitals, canteens) require test reports for procurement audits; a lack of documentation can disqualify suppliers before price is even discussed.

Procurement teams should therefore treat compliance documentation as an essential line-item in RFQs and supplier scorecards — not an optional add-on.

Stainless Steel Cookware Supplier Compliance Checklist

When evaluating factories or trading partners, insist on a complete stainless steel cookware certification package tailored to your target markets:

- MTRs (Mill Test Reports) for base coil/plate showing alloy chemistry (304/316/430, etc.).

- Finished article LFGB test report (if you sell in EU/Germany) that specifies the test conditions and use case.

- Third-party migration/heavy-metal test reports relevant to your market (FDA-style reports for U.S. sales, LFGB for EU).

- Passivation / electropolish certificates, where applicable — surface treatment affects migration results.

- Production QC records: batch numbers, in-line thickness logs, and AQL records.

- Sample retention & re-test policy: Who pays for follow-up testing if a batch fails? Please put it in the contract.

Make sample sign-off contingent on reviewing these documents; a signed PP (pre-production) sample plus the document package should be prerequisites for mass production.

Risks of Selling Without Proper Certifications

Underestimating certification risk leads to real costs:

- Customs detention or destruction in the EU if LFGB tests fail.

- Platform delisting or forced recalls on major marketplaces.

- Contractual exposure with large institutional buyers demanding compliance.

- Brand and legal risk from consumer harm claims or regulatory action.

Certification is an insurance policy: modest upfront testing and MTR checks prevent disproportionate downstream costs.

Conclusion

For importers, distributors, and brand owners, LFGB and FDA frameworks are not academic distinctions — they’re practical tools that define market access, reduce liability, and improve commercial performance.

Treat stainless steel cookware certification as a procurement must-have: require MTRs, finished-article LFGB reports for EU sales, and documented FDA compliance for North American markets.

Doing so will make your sourcing faster, safer, and more commercially resilient — and it will protect the trust you sell to customers.

About Hengguang

Hengguang is recognized as a top kitchenware manufacturer, producing stainless steel cookware engineered for durability, heat efficiency, and food-contact safety. We support wholesale stainless steel cookware supply and develop custom stainless steel cookware solutions built around precise material selection, multi-layer construction options, and controlled forming processes. Our in-house facility integrates polishing, pressing, and inspection units, allowing stable lead times and consistent performance across every production batch.