You have likely seen “18/8” or “18/10” on the packaging of some/all of your stainless steel cookware, and you’ve likely never referenced it as stainless steel cookware if you ever asked yourself or wondered what it meant on a pot or pan, here’s the abridged and easy answer: those numbers (18/8, 18/10) mean in regard to the mix of the alloy — meaning the amount of chromium and nickel — and that will impact its corrosion resistance, shine, and formabilty.

A properly chosen piece of stainless steel cookware gives you durability and food safety, but reading the stainless steel cookware label correctly is prior to that. Now, Hengguang, a professional kitchenware manufacturer, is writing to show you more about this label.

What the Numbers Mean

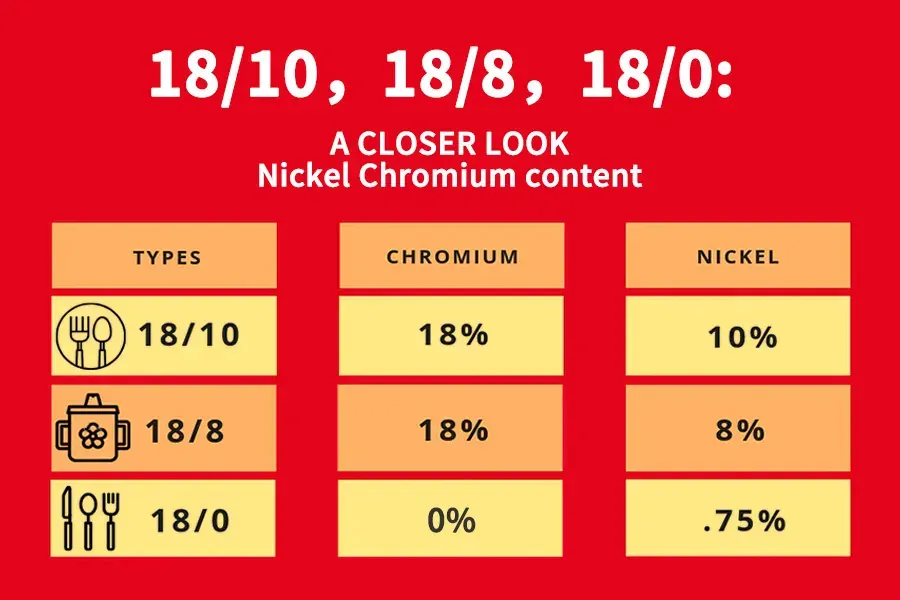

Numbers such as 18/8 and 18/10 are shorthand for the alloy’s chromium and nickel content:

- First number (18) means that there is nealy 18% chromium (Cr) in the alloy. Chromium can create a passive oxide layer that prevents rust and improves corrosion resistance.

- Second number (8 or 10) refers to the percentage of nickel (Ni) the alloy contains. Nickel stabilizes the austenitic structure, adds ductility, improves polishability, and slightly enhances corrosion resistance.

So 18/8 typically refers to the family of 304 stainless, while 18/10 indicates a slightly higher nickel content in the same family. 18/10 stainless steel 304 is synonymous with high-quality 304 stainless steel or 316 stainless steel in the tableware and kitchenware industry, because the standard for stainless steel 316 is 16% -18% chromium, 10% -14% nickel, and contains molybdenum.

Why Chromium and Nickel Matter in Practice

- Corrosion resistance: Higher chromium creates a stronger passive film; higher nickel boosts resistance to acidic foods and repeated dishwasher cycles. In typical home use, the difference between 18/8 and 18/10 is small, but in coastal or heavily salted environments, extra nickel helps, so the 18/10 stainless steel cookware may be a better choice.

- Finish and brightness: Nickel makes stainless steel easier to polish to a mirror finish — a cosmetic plus for restaurant-facing equipment.

- Workability: Nickel improves formability and weldability, which matters for complex parts like rolled rims and welded handles. It can bring you a more aesthetic appearance.

The numbers on the stainless steel cookware label tell you how the metal will behave over time.

Other Common Grades You’ll See on Labels

A quick cheat sheet to pair with label-reading:

- 304 (18/8, 18/10): Most common food-grade alloy. It features excellent corrosion resistance and formability, it is the preferred choice for daily household and commercial kitchen utensils. Great all-round performance.

- 316: Contains molybdenum (Mo); better resistance to chlorides and salt — ideal for coastal kitchens. Due to its excellent resistance to chloride and salt corrosion

- 430 (18/0): The Ferritic stainless steel family, magnetic, and lower cost — sometimes used for induction bases, but less corrosion-resistant.

- 201: Lower nickel substitute; cheaper but less suited to long-term food contact in corrosive environments. Not recommended for the catering industry.

All of these options may appear on a stainless steel cookware product spec or stainless steel cookware label; knowing the basics helps you match material to use-case.

Construction Matters More Than A Single Number

While labels like 18/8 are useful, the real cooking performance often depends on construction:

- Clad (tri-ply / 5-ply): Fusing high thermal conductivity materials such as aluminum or copper between stainless steel layers can ensure uniform and rapid heat transfer. An 18/10 tri-ply pan often outperforms a thin 18/10 disc-clad model.

- Total thickness (mm) and base design determine warp resistance and heat stability. It is the key to preventing hot spots and bottom warping.

- Handle attachment and weld quality affect safety and lifespan. Directly related to the safety and long-term reliability.

- Passivation and surface finish: Passivation-treated stainless steel has better corrosion resistance; finishes like electropolish, mirror, brushed influence corrosion resistance and cleanability.

So read the full stainless steel cookware label, not just the alloy shorthand.

How to Read a Stainless Steel Cookware Label — Step-by-step Checklist

- Find the alloy grade (e.g., 18/10, 304, 316). This tells you the base metal. Make sure the corrosion resistance level and suitability for use of the base metal meet your requirements.

- Check construction — tri-ply, 5-ply, fully-clad, or disc-clad. A clad pan can deliver a better heat spread.

- Look for thickness or gauge — Find the thickness of the pot body (especially the bottom) in millimeters. Higher quality and thicker materials (such as 2.5mm or more) mean superior heat storage and resistance to thermal deformation.

- Verify induction compatibility — magnetic layer or 18/0 base often noted.

- Request certification for B2B purchases — MTR (Mill Test Report), LFGB/FDA, or SGS test results if needed.

A careful read of the stainless steel cookware label and spec sheet prevents surprises after installation or first use.

Practical Buying Guidance (Home and Commercial)

- Home cooks: A well-built 18/10 tri-ply skillet or saucepan balances usability and longevity. The difference between 18/8 and 18/10 is subtle for everyday use.

- Professional kitchens / coastal locations: Prefer 316 or specify 316L for welded items. Insist on MTRs and passivation certificates.

- Budget contexts: If price is tight, 18/0 (430) may be acceptable for non-critical parts, but avoid it for long-term direct food contact where corrosion risk is higher.

Remember: a heavy, well-clad pan with 18/8 or 18/10 chemistry often outperforms a thin pan labeled 18/10.

Care, Warranty, and Lifespan Expectations

Proper care extends service life regardless of 18/8 or 18/10:

- Avoid prolonged exposure to strong chlorides and bleach.

- Dry promptly to prevent spotting.

- Use non-abrasive cleaners; occasional electropolish restores shine.

With good construction and maintenance, stainless steel cookware in the 304 family typically lasts a decade or more in household use; commercial life depends on workload and care.

Conclusion

Examining the details of the complete label on some/all of stainless steel cookware will give you total purchasing power: it does matter what the 18/8, 18/10, etc., means (an indicator of the composition of the alloy), but quality and specifications (material characteristics — build, thickness, quality control) determine cooking performance, durability, and ease of use. You can spend a fair amount on specifications — alloy grade (303, 304, 316), ply (one piece vs multiple), thickness (gauge), and certification (grade and structure, sustainability level) to make more reliable, thumping cookware buying decisions that return dividends every year and each time.

About Hengguang

Hengguang is a professional stainless steel kitchenware manufacturer specializing in stainless steel kitchenware manufacturing. Our tri-ply stainless steel construction ensures superior heat distribution, durability, and cooking performance.

With standardized production processes and strict quality control, every piece of kitchenware of your custom stainless steel kitchenware solution meets global standards. As a trusted stainless steel kitchenware supplier, we combine large-scale manufacturing with strong wholesale advantages, providing reliable supply and fast delivery for global partners.

Quick FAQ

Q: Is 18/10 always better than 18/8?

A: Slightly superior corrosion resistance and shine, but in normal home conditions, the practical difference is minimal.

Q: Does higher nickel make it unsafe?

A: No — nickel percentages in food-grade alloys are regulated and safe for cookware. Certifications and MTRs confirm compliance.

Q: Should I trust vague labels that only say “stainless”?

A: No — always ask for grade and construction details, especially for bulk or commercial purchases.